Exploring The Brilliance Of Metallised Mylar: A Guide To Its Uses And Benefits

Welcome to our comprehensive guide on the brilliance of metallised Mylar! In this article, we delve deep into the uses and benefits of this innovative material, uncovering a world of possibilities for various industries and applications. From its reflective properties to its durability and versatility, metallised Mylar offers a range of advantages that make it a top choice for countless projects. Join us as we explore the endless potential of this remarkable material and discover how it can enhance your next endeavor.

- An Introduction to Metallised Mylar: What Is It and How Is It Made?

Metallised Mylar, also known as metallised polyester film, is a versatile material that is being used in a wide range of industries due to its unique properties and benefits. In this article, we will delve into the world of metallised Mylar, exploring what it is, how it is made, and its various uses and benefits.

What is Metallised Mylar?

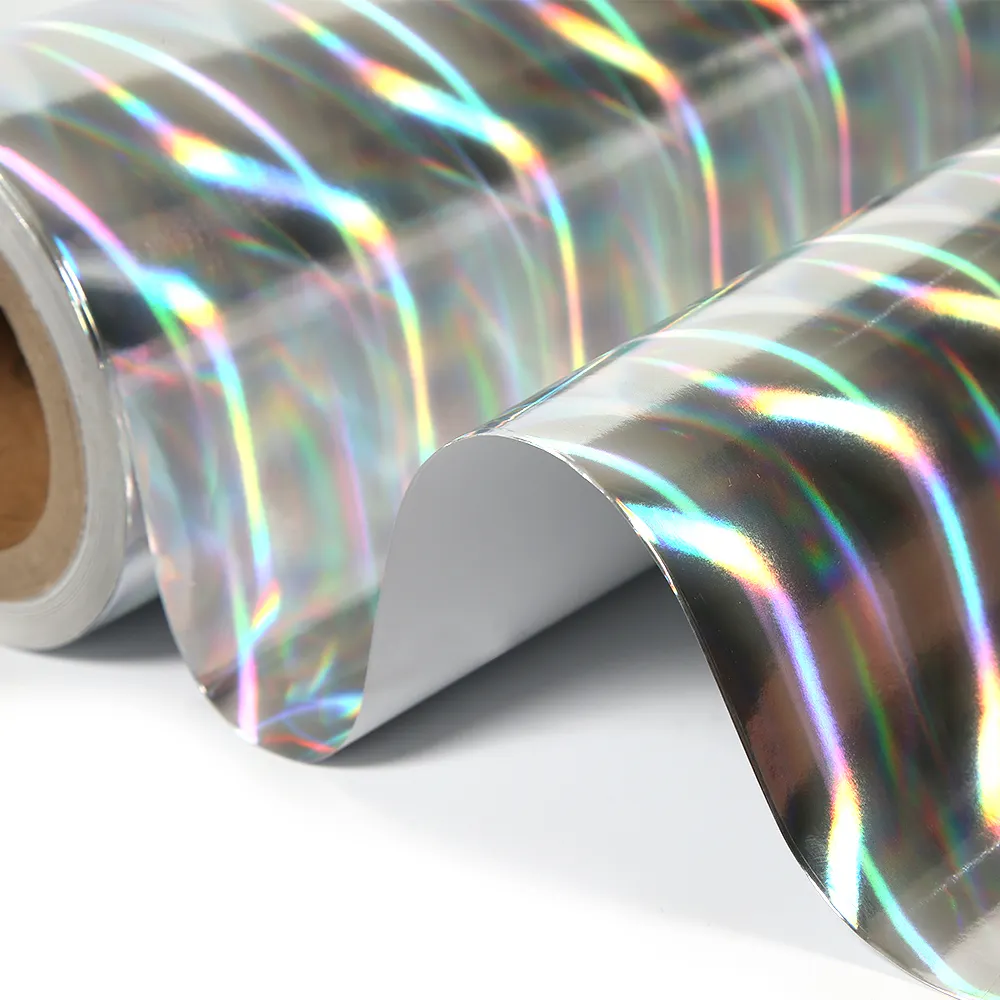

Mylar is a brand name for a type of polyester film that is known for its high tensile strength, durability, and chemical resistance. Metallised Mylar takes this versatile material to the next level by coating it with a thin layer of metal, typically aluminum. This metallisation process gives Mylar added properties such as enhanced barrier properties, conductivity, and reflectivity.

How is Metallised Mylar Made?

The process of metallising Mylar involves vacuum deposition of a thin layer of metal onto the surface of the polyester film. This is typically done using a process called sputter coating or physical vapor deposition, where the metal is evaporated in a vacuum chamber and then deposited onto the Mylar film. The result is a thin, uniform layer of metal that is tightly adhered to the polyester film, creating a flexible, lightweight material with a metallic appearance.

Uses of Metallised Mylar

Metallised Mylar has a wide range of uses across various industries. One of the most common applications is in packaging, where it is used as a barrier film to protect food, pharmaceuticals, and other sensitive products from moisture, oxygen, and light. The metallised layer helps to create an impermeable barrier that extends the shelf life of the packaged products.

In addition to packaging, metallised Mylar is also used in the electronics industry for applications such as flexible circuits, EMI shielding, and insulation. Its high reflectivity and conductivity properties make it ideal for use in reflective insulation, printed circuit boards, and other electronic components.

Benefits of Metallised Mylar

There are several key benefits to using metallised Mylar in various applications. Its high reflectivity makes it an excellent choice for reflective insulation, helping to reduce heat transfer and improve energy efficiency. The metal coating also provides excellent barrier properties, making it ideal for protecting sensitive products from environmental factors.

Furthermore, metallised Mylar is lightweight, flexible, and easy to work with, making it a versatile material for a wide range of applications. Its high tensile strength and durability ensure that it can withstand harsh conditions without tearing or degrading, making it a reliable choice for long-term use.

In conclusion, metallised Mylar is a valuable material with a wide range of uses and benefits. Its unique properties make it an ideal choice for applications requiring barrier properties, reflectivity, and conductivity. By understanding what metallised Mylar is, how it is made, and its uses and benefits, we can appreciate the brilliance of this versatile material and its potential to revolutionize industries across the board.

- The Versatility of Metallised Mylar: Applications in Various Industries

Metallised Mylar is a versatile material that has found its way into a myriad of industries due to its unique properties and benefits. From food packaging to aerospace technology, metallised Mylar has become a go-to material for companies looking to improve their products and streamline their processes. In this article, we will explore the brilliance of metallised Mylar and delve into its various applications in different industries.

One of the key advantages of metallised Mylar is its ability to reflect heat and light. This makes it an ideal material for use in the food industry, where it can be used to create packaging that helps keep food fresh for longer. The reflective properties of metallised Mylar help to maintain the temperature inside the packaging, preventing heat from escaping and extending the shelf life of the product. In addition, metallised Mylar is also moisture-resistant, which further helps to preserve the quality of the food inside.

Another industry that has embraced the versatility of metallised Mylar is the aerospace sector. The material's lightweight nature and high tensile strength make it an ideal choice for use in aircraft components. Metallised Mylar is often used in insulation panels and as a protective layer for sensitive equipment, helping to ensure the safety and efficiency of aircraft systems. Its ability to reflect heat and light also makes it an excellent choice for use in spacecraft, where maintaining optimal temperatures is crucial.

In the healthcare industry, metallised Mylar has also found a range of applications. The material is often used in medical packaging, where its ability to provide a barrier against moisture and contaminants is essential. Metallised Mylar is also used in medical equipment, where its reflective properties can help to protect sensitive instruments from damage caused by heat or light. Additionally, metallised Mylar is commonly used in medical imaging devices, where its reflective properties can help to improve the quality of images produced.

The automotive industry is another sector that has benefitted from the versatility of metallised Mylar. The material is often used in the production of automotive insulation and soundproofing materials, where its ability to reflect heat and sound can help to improve the comfort and performance of vehicles. Metallised Mylar is also used in the production of automotive airbags, where its lightweight nature and high tensile strength make it an ideal choice for use in safety systems.

In conclusion, metallised Mylar is a truly remarkable material that has revolutionized a wide range of industries. Its reflective properties, moisture resistance, and lightweight nature make it an ideal choice for use in a variety of applications, from food packaging to aerospace technology. As companies continue to explore the benefits of metallised Mylar, we can expect to see even more innovative uses for this versatile material in the future.

- Advantages of Using Metallised Mylar in Packaging and Insulation

Metallised Mylar, also known as metallized polyester film, is a popular material used in a variety of industries for packaging and insulation purposes. This versatile material offers numerous advantages that make it a preferred choice for many applications. In this comprehensive guide, we will explore the brilliance of metallised Mylar, discussing its uses and benefits in detail.

One of the key advantages of using metallised Mylar in packaging is its superior barrier properties. This material has a high resistance to moisture, oxygen, and other gases, making it ideal for keeping products fresh and extending their shelf life. Additionally, metallised Mylar provides excellent protection against UV radiation, preventing damage to light-sensitive products.

Another benefit of metallised Mylar is its lightweight and flexible nature. This makes it easy to handle and manipulate, allowing for efficient packaging solutions. The material can be easily cut, folded, and sealed to create customized packaging solutions for a wide range of products. Its flexibility also makes it an ideal choice for applications that require a form-fitting packaging solution.

In addition to its packaging advantages, metallised Mylar is also commonly used for insulation purposes. The reflective properties of the metallised layer help to reflect heat and light, making it an effective insulator. This can help to regulate temperature and reduce energy costs in various applications, such as in buildings, vehicles, and electronic devices.

Furthermore, metallised Mylar is a cost-effective solution for both packaging and insulation needs. Compared to other materials, such as aluminum foil, metallised Mylar offers similar barrier properties at a fraction of the cost. This makes it a more affordable option for businesses looking to reduce their packaging and insulation costs without sacrificing quality.

Overall, the brilliance of metallised Mylar lies in its versatility, durability, and cost-effectiveness. Whether used for packaging delicate products or insulating buildings, this material offers a wide range of benefits that make it a valuable choice for various industries. With its superior barrier properties, flexibility, and affordability, metallised Mylar is a reliable and efficient solution for all your packaging and insulation needs.

- Environmental Benefits of Metallised Mylar: A Sustainable Option

Metallised Mylar is a versatile material that is gaining popularity for its numerous uses and benefits. From enhancing the shelf life of food products to providing insulation in buildings, Metallised Mylar offers a wide range of applications that contribute to sustainability and environmental protection.

One of the key environmental benefits of Metallised Mylar is its recyclability. Unlike other materials that end up in landfills and contribute to pollution, Metallised Mylar can be easily recycled and reused. This helps reduce waste and minimizes the impact on the environment. Additionally, the production process of Metallised Mylar requires less energy compared to traditional materials, making it a more sustainable option.

Another environmental benefit of Metallised Mylar is its ability to reduce energy consumption. When used as insulation in buildings, Metallised Mylar reflects heat and prevents it from escaping, thus reducing the need for heating and cooling systems. This not only saves energy but also reduces greenhouse gas emissions, making it a more environmentally friendly choice.

In the packaging industry, Metallised Mylar plays a crucial role in extending the shelf life of food products. Its barrier properties protect the contents from moisture, oxygen, and light, preventing spoilage and reducing food waste. This not only benefits the environment by reducing the amount of food that ends up in landfills but also helps conserve resources by extending the lifespan of products.

Metallised Mylar is also widely used in the production of solar panels, where its reflective properties help maximize the absorption of sunlight. By harnessing the power of the sun, solar panels generate clean and renewable energy, reducing reliance on fossil fuels and lowering carbon emissions. This makes Metallised Mylar a key player in the shift towards sustainable energy sources.

Moreover, Metallised Mylar is a lightweight material that is easy to transport and handle, further reducing its environmental footprint. Its durability and resistance to punctures and tears ensure that it can be reused multiple times, making it a cost-effective and sustainable option.

In conclusion, Metallised Mylar offers a range of environmental benefits that make it a sustainable choice for various industries. From packaging to insulation, this versatile material helps reduce waste, save energy, and protect the environment. By exploring the brilliance of Metallised Mylar and understanding its uses and benefits, we can make informed choices that contribute to a greener and more sustainable future.

- Innovations in Metallised Mylar Technology: Future Prospects and Developments

Metallised Mylar, also known as metalized polyester or metallized polyethylene terephthalate, is a type of film that has been coated with a thin layer of metal, typically aluminum, to enhance its properties. This innovative technology has revolutionized various industries and opened up a world of possibilities for future developments.

One of the key benefits of metallised Mylar is its superior barrier properties. The metal coating provides a protective barrier against moisture, oxygen, and other gases, making it an ideal material for packaging applications. This has led to its widespread use in the food and beverage industry, where it is used for packaging perishable goods such as coffee, snacks, and pet food. The barrier properties of metallised Mylar also make it an excellent material for flexible electronics and medical devices, where a reliable barrier against external factors is crucial.

In addition to its barrier properties, metallised Mylar also offers excellent reflectivity and conductivity. The metal coating on the film reflects light and heat, making it a popular choice for insulation and reflective applications. This property is particularly useful in the construction industry, where metallised Mylar is used in insulation, radiant barriers, and reflective coatings to improve energy efficiency and reduce heat transfer. The conductivity of metallised Mylar also makes it a valuable material for electronic components and solar panels, where it can be used as a conductive film or coating.

The future prospects for metallised Mylar technology are promising, with ongoing research and development focused on enhancing its properties and expanding its applications. Innovations in metallised Mylar technology are opening up new possibilities in the fields of nanotechnology, photonics, and flexible electronics. Researchers are exploring ways to improve the adhesion strength of the metal coating, enhance the optical properties of the film, and develop new methods for patterning and structuring metallised Mylar to create complex devices and structures.

One exciting development in metallised Mylar technology is the use of nanostructures and metamaterials to create materials with unique optical and electromagnetic properties. By manipulating the structure and composition of the metal coating on the film, researchers can control the reflection, absorption, and transmission of light and other forms of electromagnetic radiation. This has the potential to revolutionize applications in optics, photonics, and telecommunications, where precise control over light and electromagnetic waves is essential.

Overall, metallised Mylar technology offers a wide range of benefits and applications, from packaging and insulation to electronics and optics. With ongoing innovations and developments in the field, the future prospects for metallised Mylar look bright, with exciting new opportunities on the horizon. As researchers continue to explore the brilliance of metallised Mylar, we can expect to see even more groundbreaking advancements in the years to come.

Conclusion

In conclusion, the versatility and countless benefits of metallised Mylar make it a must-have material for a wide range of applications. From its ability to reflect heat and light to its durability and flexibility, this innovative material has revolutionized industries such as packaging, insulation, and electronics. Whether you are looking to protect your products, insulate your home, or enhance your electronics, metallised Mylar offers a cost-effective and efficient solution. Its brilliance truly knows no bounds, and the possibilities for its use are endless. Start exploring the benefits of metallised Mylar today and revolutionize your projects with this exceptional material.