Shining A Light On Metalized Film: The Cutting-Edge Technology Transforming Packaging And Printing

In the world of packaging and printing, a revolutionary technology is taking center stage: metalized film. This cutting-edge innovation is not only transforming the way products are packaged and presented, but it is also revolutionizing the printing industry as a whole. Join us as we shine a light on the incredible capabilities of metalized film and explore how this technology is reshaping the future of packaging and printing.

- The Rise of Metalized Film in Packaging Technology

In today's fast-paced world, the packaging and printing industry is constantly evolving to meet the needs and demands of consumers. One cutting-edge technology that is transforming the industry is metalized film. This innovative material is revolutionizing the way products are packaged and presented to consumers, offering a multitude of benefits that make it a popular choice among manufacturers.

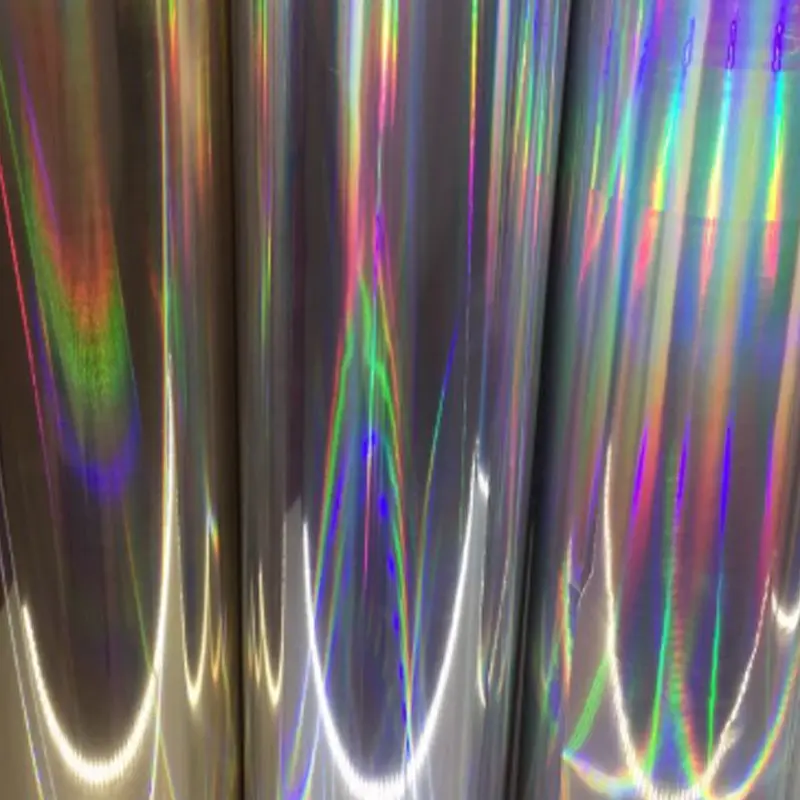

Metalized film, also known as metallized film, is a thin layer of metal that is laminated onto a flexible plastic substrate. This process creates a shiny, reflective surface that not only enhances the visual appeal of the packaging but also provides a barrier against moisture, oxygen, and light. This barrier protection helps to extend the shelf life of products and maintain their freshness and quality.

One of the key advantages of metalized film is its versatility. It can be used in a wide range of packaging applications, from food and beverage packaging to personal care products and pharmaceuticals. Its ability to be printed on with vibrant colors and intricate designs makes it an ideal choice for brands looking to stand out on crowded store shelves and catch the eye of consumers.

In addition to its visual appeal, metalized film also offers practical benefits for manufacturers. Its lightweight and flexible nature make it easy to handle and package, reducing shipping costs and improving overall efficiency. The durability of metalized film also ensures that products remain protected during transit, reducing the risk of damage or spoilage.

Furthermore, metalized film is environmentally friendly, as it is often recyclable and can be reused in other packaging applications. This sustainability factor is becoming increasingly important to consumers who are more conscious of the environmental impact of their choices.

The rise of metalized film in packaging technology is a testament to the industry's commitment to innovation and advancement. As consumers continue to demand high-quality products with memorable packaging, manufacturers are turning to metalized film to meet these expectations. Its ability to combine aesthetic appeal with practical functionality makes it a game-changing material in the world of packaging and printing.

In conclusion, metalized film is a game-changer in the packaging and printing industry. Its unique combination of visual appeal, barrier protection, and practical benefits make it a popular choice among manufacturers looking to make a lasting impression on consumers. As technology continues to advance, we can expect to see metalized film play an even more significant role in shaping the future of packaging and printing.

- Advancements in Metalized Film Printing Techniques

Metalized film has long been a popular choice in the packaging and printing industry due to its ability to add a touch of luxury and sophistication to products. However, advancements in metalized film printing techniques have taken this versatile material to new heights, revolutionizing the way packaging and printing is done.

One of the key advancements in metalized film printing techniques is the use of advanced digital printing technology. This technology allows for more precise and detailed designs to be printed on metalized film, resulting in stunning visuals that can truly make a product stand out on the shelves. Digital printing also offers faster turnaround times and lower costs, making it a more efficient option for packaging and printing companies.

Another key advancement in metalized film printing techniques is the use of special coatings and finishes. These coatings can enhance the visual appeal of the film by adding special effects such as gloss, matte, or holographic finishes. These finishes not only make the packaging more visually appealing but also provide added protection and durability to the film, ensuring that the product inside remains safe and secure.

Furthermore, advancements in metalized film printing techniques have also led to the development of environmentally friendly options. Sustainable printing techniques such as water-based inks and recyclable films are becoming more popular in the industry, as companies strive to reduce their carbon footprint and create more eco-friendly packaging solutions.

The use of metalized film in packaging and printing is not limited to just aesthetic purposes. Metalized film also offers practical benefits such as increased shelf life and product freshness. The barrier properties of metalized film help to protect the contents from moisture, light, and oxygen, extending the shelf life of perishable goods and ensuring that they reach consumers in optimal condition.

In addition to its practical benefits, the use of metalized film in packaging and printing also helps to differentiate a brand from its competitors. The luxurious look and feel of metalized film can help to create a premium branding experience for consumers, making a product more desirable and increasing its perceived value.

Overall, advancements in metalized film printing techniques have transformed the packaging and printing industry, offering a wide range of benefits for companies looking to enhance their products and stand out in a competitive market. With the use of advanced digital printing technology, special coatings and finishes, and sustainable options, metalized film has become an essential tool for companies looking to create visually stunning and environmentally friendly packaging solutions.

- The Benefits of Metalized Film for Branding and Quality

In today’s competitive market, brands are constantly looking for ways to stand out on the shelves and leave a lasting impression on consumers. One cutting-edge technology that is transforming the world of packaging and printing is metalized film. This innovative material offers a range of benefits for both branding and quality, making it a popular choice among companies looking to elevate their products.

Metalized film is a type of packaging material that has been treated with a thin layer of metal, typically aluminum. This process gives the film a shiny, reflective appearance that catches the eye and creates a premium look and feel. Brands can use metalized film to create striking packaging designs that draw attention on the shelves and communicate the quality and value of their products.

One of the key benefits of metalized film for branding is its ability to enhance the visual appeal of packaging. The reflective surface of the film can make colors appear more vibrant and images more dynamic, making the product stand out from the competition. In addition, the shiny finish of metalized film adds a touch of luxury and sophistication to the packaging, making it more appealing to consumers looking for high-quality products.

Metalized film also offers practical benefits for branding, such as durability and versatility. The metal layer provides an extra layer of protection for the product, helping to keep it safe during shipping and storage. Additionally, metalized film is flexible and easy to work with, allowing brands to create unique packaging designs that reflect their brand identity and set them apart from competitors.

In terms of quality, metalized film is a top choice for packaging and printing for several reasons. Firstly, the metal layer on the film provides excellent barrier properties, making it ideal for food products and other items that need to be protected from moisture, oxygen, and light. This helps to extend the shelf life of the product and maintain its freshness and quality.

Furthermore, metalized film is heat-sealable, allowing for easy and secure closure of the packaging. This ensures that the product remains sealed and protected until it is ready to be used, reducing the risk of contamination or spoilage. Metalized film is also compatible with a variety of printing techniques, including offset, flexography, and digital printing, making it a versatile choice for brands looking to create unique and eye-catching designs for their products.

Overall, metalized film is a cutting-edge technology that offers a wide range of benefits for both branding and quality in packaging and printing. Its shiny, reflective appearance helps brands to create visually appealing designs that stand out on the shelves, while its durability and barrier properties ensure that the product remains fresh and protected. With its versatility and practical benefits, metalized film is becoming an increasingly popular choice for companies looking to elevate their packaging and printing and leave a lasting impression on consumers.

- Innovations in Metalized Film Finishing and Coating

Metalized film has long been a staple in the packaging and printing industries, providing a sleek and modern finish to products. However, recent innovations in metalized film finishing and coating have taken this technology to new heights, offering even more possibilities for creative and eye-catching designs.

One of the key advancements in metalized film technology is the use of enhanced coatings, which not only give the film a glossy and reflective surface but also provide additional benefits such as improved durability and enhanced barrier properties. These coatings can be tailored to specific applications, whether it be for food packaging, cosmetic packaging, or even labels and decals.

Another innovation in metalized film technology is the development of specialized finishes that enhance the overall look and feel of the packaging. For example, holographic finishes can create a striking visual effect that captures the attention of consumers, while matte finishes offer a more subtle and sophisticated appearance. These finishes can be combined with coatings to achieve custom effects that suit the branding and messaging of a particular product.

In addition to aesthetic enhancements, advancements in metalized film technology have also focused on increasing functionality and sustainability. One notable development is the use of metalized film as a replacement for traditional materials like aluminum foil, which can reduce the environmental impact of packaging production. Metalized film can also be combined with recyclable materials to create eco-friendly packaging solutions that meet the demands of environmentally conscious consumers.

Furthermore, innovations in metalized film technology have led to improvements in printing techniques, allowing for more intricate and dynamic designs to be applied to the film. High-definition printing technology enables fine details and vibrant colors to be reproduced with precision, resulting in packaging that stands out on the shelf and engages consumers on a visual level.

Overall, the advancements in metalized film finishing and coating have transformed the packaging and printing industries, offering a range of benefits for manufacturers and consumers alike. From improved durability and aesthetics to enhanced functionality and sustainability, metalized film technology continues to evolve and shape the future of packaging and printing. As brands look for innovative ways to differentiate themselves in a competitive market, metalized film remains a versatile and dynamic choice that can elevate the overall look and appeal of their products.

- The Future of Metalized Film in Sustainable Packaging Solutions

Metalized film has long been a staple in the packaging and printing industry, providing a glossy, metallic finish that enhances the visual appeal of products. However, with the growing demand for sustainable packaging solutions, the future of metalized film is now being reimagined.

As consumers become more conscious of their environmental impact, brands are under increasing pressure to adopt more sustainable practices. This has led to a shift towards eco-friendly packaging materials, with metalized film emerging as a key player in the transition.

One of the main challenges with traditional metalized film is its non-biodegradable nature. Made from a combination of plastic and metal, it has contributed to the global plastic waste crisis. However, advancements in technology have paved the way for the development of biodegradable and compostable metalized films that offer the same visual impact without the environmental harm.

These new sustainable metalized films are made from plant-based materials such as cellulose or starch, which break down naturally in the environment. This not only reduces the carbon footprint of packaging but also aligns with the circular economy principles of recycling and reusing resources.

In addition to being biodegradable, sustainable metalized films also offer other advantages. They are lightweight, which reduces transportation costs and emissions. They are also versatile, allowing for customization in terms of colors, patterns, and finishes, further enhancing the visual appeal of packaging.

Furthermore, sustainable metalized films are also compatible with various printing techniques, such as flexography and digital printing. This allows for high-quality graphics and branding on packaging, ensuring that products stand out on the shelf and attract consumers.

The adoption of sustainable metalized films in packaging and printing is not just a trend – it is a necessity. As regulations around single-use plastics tighten and eco-conscious consumers demand more sustainable options, brands must embrace these innovative materials to stay competitive.

In conclusion, the future of metalized film in sustainable packaging solutions is bright. With the development of biodegradable and compostable alternatives, brands now have the opportunity to enhance the visual appeal of their products while reducing their environmental impact. By embracing this cutting-edge technology, the packaging and printing industry can pave the way towards a more sustainable future.

Conclusion

In conclusion, the use of metalized film in packaging and printing has revolutionized the industry by offering a wide range of benefits such as enhanced product aesthetics, increased shelf appeal, and improved product protection. This cutting-edge technology has paved the way for innovative design possibilities and opportunities to create eye-catching packaging solutions. As brands continue to strive for differentiation and sustainability, metalized film is sure to play a crucial role in meeting these goals. With its ability to captivate consumers and protect products, metalized film truly shines a light on the future of packaging and printing.