Unveiling The Benefits Of Metallized Mylar Film

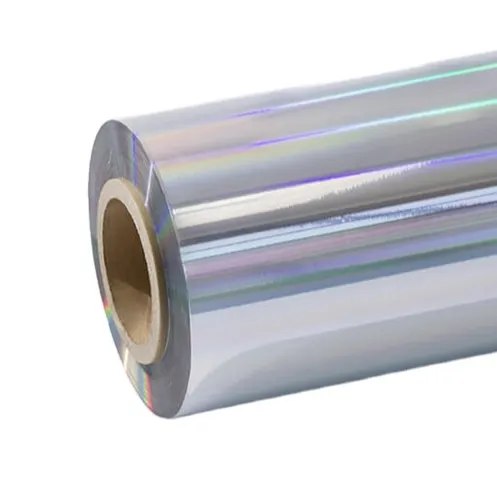

Discover the endless possibilities and advantages of using metallized Mylar film in your packaging and labeling needs. From increased durability and shelf life to enhanced product presentation, learn how this innovative material can revolutionize your business operations. Dive into the world of metallized Mylar film and unlock a new level of success for your products.

- An Introduction to Metallized Mylar Film

Metallized mylar film, also known as metallized polyester film, is a type of material that has been gaining popularity in various industries due to its versatile properties and benefits. In this article, we will delve into the world of metallized mylar film and explore its numerous advantages.

To begin with, metallized mylar film is a polyester film that has been coated with a thin layer of metal, typically aluminum. This metallization process gives the film a shiny, metallic appearance while also enhancing its barrier properties. The aluminum coating acts as a barrier to light, moisture, and oxygen, making metallized mylar film an excellent choice for packaging materials.

One of the key benefits of metallized mylar film is its superior barrier properties. The metal coating creates a protective barrier that helps to keep out moisture, oxygen, and other gases that can degrade the quality of the packaged contents. This makes metallized mylar film ideal for packaging perishable items such as food, pharmaceuticals, and electronics.

Another advantage of metallized mylar film is its high tensile strength and durability. The polyester base of the film provides excellent strength, allowing it to withstand rough handling and transportation without tearing or puncturing. This durability makes metallized mylar film a cost-effective packaging solution that can withstand the rigors of the supply chain.

In addition to its barrier properties and durability, metallized mylar film also offers excellent heat resistance. The metal coating on the film reflects infrared radiation, helping to keep the packaged contents cool and protected from heat. This makes metallized mylar film suitable for packaging items that are sensitive to temperature fluctuations, such as electronics and pharmaceuticals.

Furthermore, metallized mylar film is also lightweight and flexible, making it easy to work with and suitable for a wide range of packaging applications. Its shiny, metallic appearance can also enhance the visual appeal of packaged products, making them stand out on store shelves.

In conclusion, metallized mylar film is a versatile and cost-effective packaging material that offers numerous benefits. From its superior barrier properties to its durability and heat resistance, metallized mylar film is an ideal choice for a wide range of industries. Whether you are packaging food, electronics, or pharmaceuticals, metallized mylar film can help you protect your products and enhance your brand image.

- The Various Applications of Metallized Mylar Film

Metallized Mylar film is a versatile material that has a wide range of applications across various industries. This article will delve into the numerous benefits of using Metallized Mylar film, as well as explore the different ways in which it can be utilized.

One of the key advantages of Metallized Mylar film is its superior barrier properties. The film is made by depositing a thin layer of metal, typically aluminum, onto a polyester substrate. This metallized layer acts as a barrier to moisture, oxygen, and other gases, making it an excellent choice for packaging applications. Metallized Mylar film is commonly used in the food and pharmaceutical industries to extend the shelf life of products and maintain their freshness.

In addition to its barrier properties, Metallized Mylar film also has excellent heat resistance. This makes it an ideal material for applications where high temperatures are present, such as in electronic devices or automotive components. The film can withstand temperatures up to 300 degrees Fahrenheit, making it a reliable option for a wide range of applications.

Metallized Mylar film is also known for its excellent reflective properties. The metal layer reflects light and heat, making it a popular choice for insulating materials. The film is often used in building insulation, radiant barriers, and reflective tape. Its reflective properties help to reduce energy costs by keeping buildings cool in the summer and warm in the winter.

Another benefit of using Metallized Mylar film is its flexibility and durability. The film can be easily cut, folded, and molded into different shapes, making it a versatile material for various applications. Its durability ensures that it can withstand harsh conditions and environments, making it a reliable option for long-term use.

One of the main applications of Metallized Mylar film is in the manufacturing of flexible packaging. The film is commonly used as a barrier material in pouches, bags, and wrappers to protect products from external elements. Its excellent barrier properties help to extend the shelf life of perishable goods and maintain their quality.

Metallized Mylar film is also utilized in the production of solar panels. The film is used as a backing material for the photovoltaic cells, helping to improve their efficiency by reflecting light back onto the cells. Its heat resistance and durability make it an ideal material for this application, enabling the production of reliable and long-lasting solar panels.

In conclusion, Metallized Mylar film is a versatile material that offers numerous benefits across a wide range of applications. From its superior barrier properties to its excellent reflective properties, this material is a reliable choice for packaging, insulation, and other industrial applications. Its flexibility and durability make it a popular option for manufacturers looking for a high-performance material for their products.

- Advantages of Using Metallized Mylar Film in Packaging

Metallized Mylar film has become increasingly popular in the packaging industry due to its numerous advantages over traditional packaging materials. This innovative material offers a range of benefits that make it an excellent choice for various packaging applications.

First and foremost, Metallized Mylar film is known for its superior barrier properties. The metallized layer on the film acts as a barrier to moisture, oxygen, and light, making it an ideal choice for packaging products that are sensitive to these elements. This barrier helps to extend the shelf life of the packaged products, preserving their freshness and quality for longer periods.

In addition to its barrier properties, Metallized Mylar film is also lightweight and flexible, making it easy to handle and transport. This makes it an ideal choice for packaging applications where weight and flexibility are important considerations, such as in the food and beverage industry. Its flexibility also allows for it to be easily folded and sealed, ensuring that the packaged products are securely enclosed.

Furthermore, Metallized Mylar film is highly durable and puncture-resistant, protecting the packaged products from damage during storage and transportation. This durability not only ensures the integrity of the packaged products but also reduces the risk of product spoilage and waste.

Another advantage of using Metallized Mylar film in packaging is its versatility. This material can be easily customized to meet specific packaging requirements, such as size, shape, and design. This flexibility allows for the creation of unique and attractive packaging solutions that help to enhance the visibility and appeal of the packaged products.

Moreover, Metallized Mylar film is also environmentally friendly. It is recyclable and can be easily reused or repurposed, reducing the environmental impact of packaging waste. This makes it a sustainable choice for businesses looking to reduce their carbon footprint and promote eco-friendly practices.

Overall, the advantages of using Metallized Mylar film in packaging are numerous. From its superior barrier properties and durability to its lightweight and flexible nature, this innovative material offers a range of benefits that make it an excellent choice for various packaging applications. Businesses looking to enhance the quality, sustainability, and appeal of their packaged products should consider using Metallized Mylar film for their packaging needs.

- Enhancing Product Shelf Life with Metallized Mylar Film

In the competitive world of product packaging, one crucial factor that sets a brand apart from its competitors is the shelf life of its products. Ensuring that products stay fresh and retain their quality for an extended period is key to customer satisfaction and loyalty. This is where metallized Mylar film comes into play, offering a range of benefits that can enhance the shelf life of various products.

Metallized Mylar film is a high-performance packaging material that consists of a thin layer of metal, typically aluminum, deposited on a polyester film. This combination of materials creates a barrier that is impermeable to moisture, gases, and light, making it an ideal choice for extending the shelf life of products.

One of the primary benefits of using metallized Mylar film for packaging is its ability to provide superior protection against external elements that can spoil or degrade the product. By forming a barrier that prevents moisture and oxygen from reaching the product, the film helps to preserve its freshness and quality. This is particularly important for products that are sensitive to moisture or oxygen, such as food items, pharmaceuticals, and electronic components.

In addition to its protective qualities, metallized Mylar film also offers excellent light-blocking properties. Exposure to light can cause products to degrade, lose color, or develop off-flavors. By shielding products from light, the film helps to maintain their appearance, flavor, and overall quality. This is particularly beneficial for products that are light-sensitive, such as certain pharmaceuticals, cosmetics, and food items.

Furthermore, metallized Mylar film is lightweight and flexible, making it easy to work with and suitable for a wide range of packaging applications. Its versatility allows for customized packaging solutions that can meet the specific needs of different products and industries. Whether it is used for wrapping individual food items, lining pouches, or creating stand-up pouches for snacks, the film can be tailored to suit the requirements of the product and enhance its shelf life.

Another advantage of using metallized Mylar film is its sustainability. The film is recyclable and can be reused, making it an environmentally friendly packaging option. By choosing packaging materials that are recyclable, brands can demonstrate their commitment to sustainability and attract eco-conscious consumers.

In conclusion, the benefits of metallized Mylar film are clear. Its protective properties, light-blocking capabilities, versatility, and sustainability make it an excellent choice for enhancing the shelf life of products. By incorporating metallized Mylar film into their packaging strategies, brands can ensure that their products remain fresh, attractive, and high-quality for longer periods, ultimately leading to increased customer satisfaction and loyalty.

- Sustainability Benefits of Choosing Metallized Mylar Film

In today's rapidly changing world, sustainability has become a key focus for businesses and consumers alike. As the demand for environmentally friendly products continues to rise, the importance of choosing sustainable packaging materials has never been more crucial. One such material that is gaining popularity for its sustainability benefits is metallized mylar film.

Metallized mylar film is a versatile packaging material that is made from a thin layer of aluminum deposited onto a polyester film. This material is known for its excellent barrier properties, which make it ideal for protecting products from moisture, light, and oxygen. In addition to its barrier properties, metallized mylar film is also lightweight, flexible, and heat-sealable, making it a popular choice for a wide range of applications.

One of the key sustainability benefits of choosing metallized mylar film is its recyclability. Unlike traditional plastics, metallized mylar film is made from a combination of aluminum and polyester, both of which are highly recyclable materials. This means that metallized mylar film can be easily recycled and reused, reducing the amount of waste that ends up in landfills.

Furthermore, metallized mylar film is also energy efficient to produce. The manufacturing process for metallized mylar film requires less energy compared to other packaging materials, making it a more sustainable choice for businesses looking to reduce their carbon footprint. Additionally, the lightweight nature of metallized mylar film means that it requires less fuel for transportation, further reducing its environmental impact.

Another key sustainability benefit of metallized mylar film is its durability and longevity. Metallized mylar film is highly resistant to tearing, punctures, and moisture, making it an ideal packaging material for products that require protection during storage and transportation. This durability means that products packaged in metallized mylar film are less likely to be damaged or wasted, leading to a reduction in overall waste and environmental impact.

In addition to its sustainability benefits, metallized mylar film also offers a range of other advantages for businesses. Its reflective properties can enhance the shelf life of products by providing protection from light and UV radiation. This makes it an ideal choice for packaging products that are sensitive to light, such as food and pharmaceuticals.

Overall, the sustainability benefits of choosing metallized mylar film make it an attractive option for businesses looking to reduce their environmental impact. From its recyclability and energy efficiency to its durability and protective properties, metallized mylar film offers a range of advantages that can help businesses meet their sustainability goals while also ensuring the quality and safety of their products. By choosing metallized mylar film as a packaging material, businesses can not only reduce their environmental footprint but also contribute to a more sustainable future for generations to come.

Conclusion

In conclusion, it is evident that the benefits of metallized Mylar film are numerous and highly advantageous in various industries. From its superior barrier properties to its ability to enhance product aesthetics and overall quality, this type of film offers a range of benefits that cannot be overlooked. Whether it's in the food packaging industry, the medical field, or even in the automotive sector, metallized Mylar film has proven to be a versatile and essential material. As technology continues to advance and demand for high-quality packaging materials grows, metallized Mylar film will undoubtedly play a crucial role in meeting these needs. With its ability to offer protection, longevity, and visual appeal, it is clear that this type of film is a valuable asset in today's fast-paced market.