HARDVOGUE Adhesive Plastic Film Makers

Product Overview

Certainly! Here is a summary of the HARDVOGUE Adhesive Plastic Film Makers product based on the detailed introduction you provided:

Product Features

**Product Overview**

Product Value

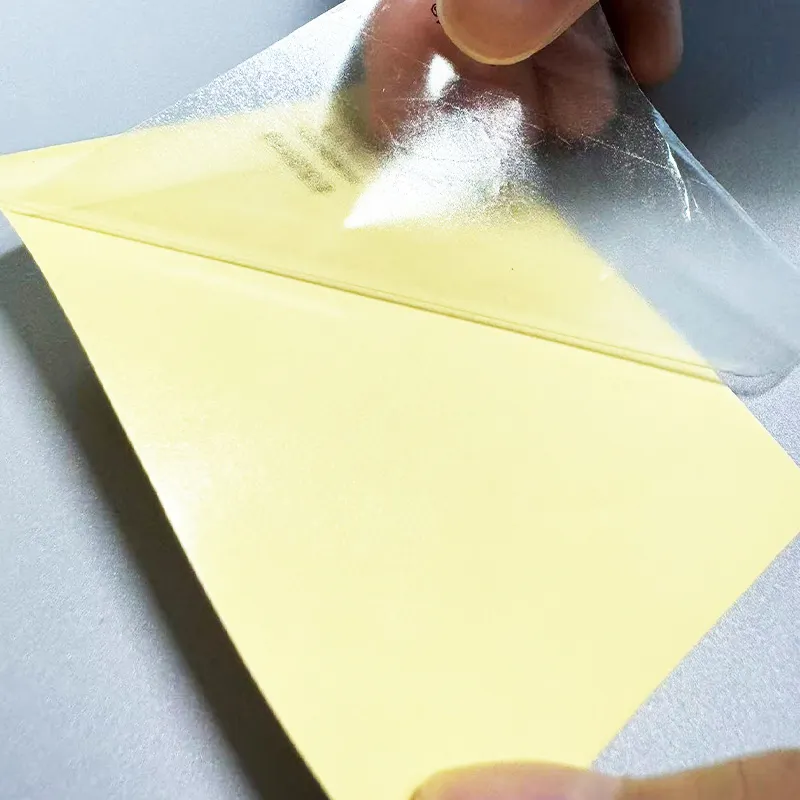

HARDVOGUE Adhesive Plastic Film Makers produce high-quality clear PET adhesive films (25/50 Micron thickness) designed primarily for printing and packaging. Manufactured with advanced technology and expert technical support, the films come in customizable sheets or reels and are certified by FSC, ISO9001, and RoHS to ensure international quality standards. The company offers reliable international customer service and OEM customization to meet diverse industrial needs.

Product Advantages

**Product Features**

Application Scenarios

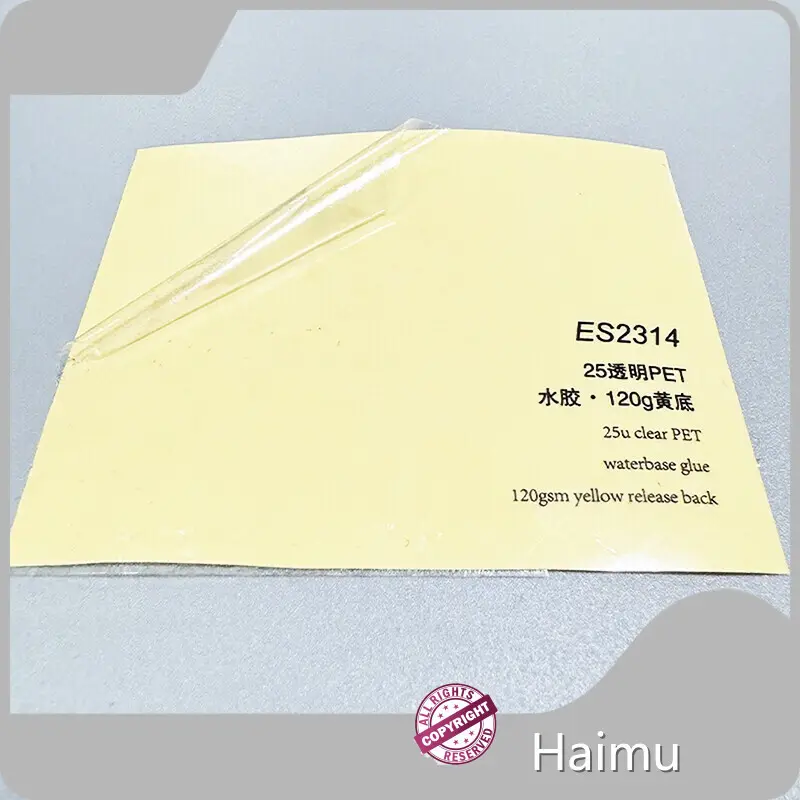

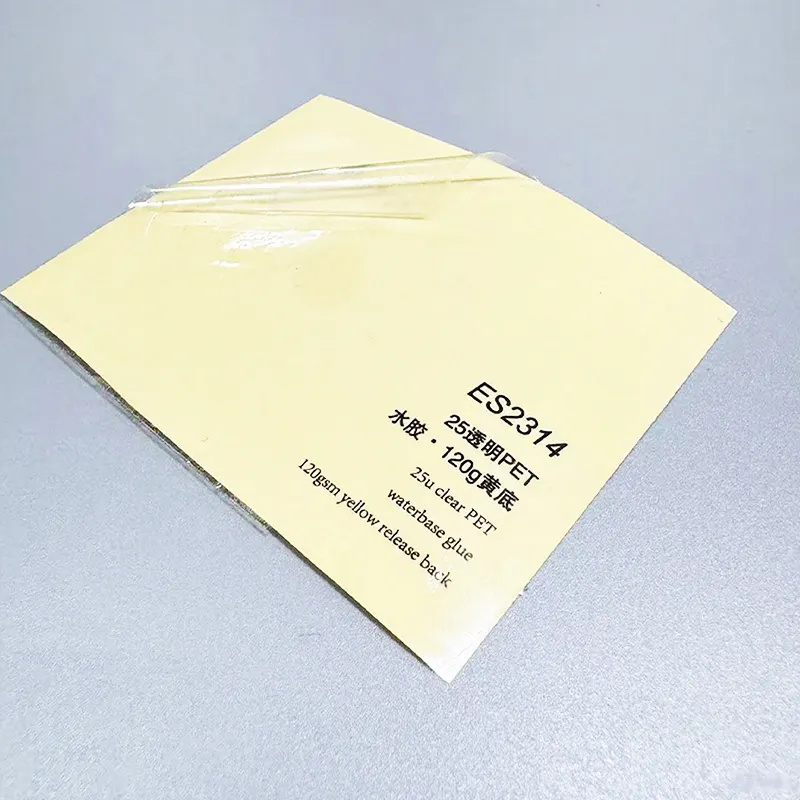

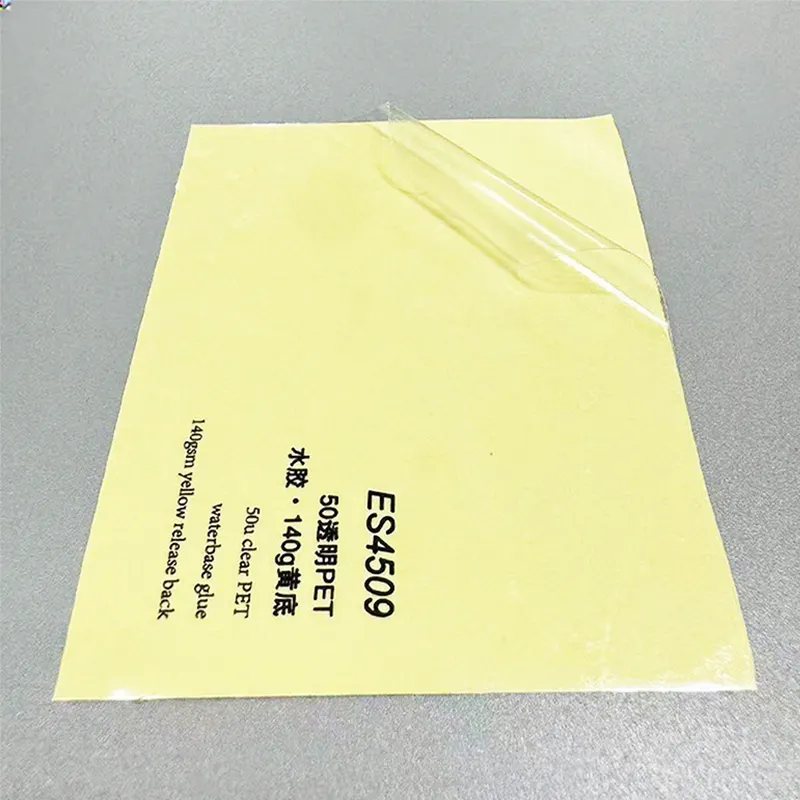

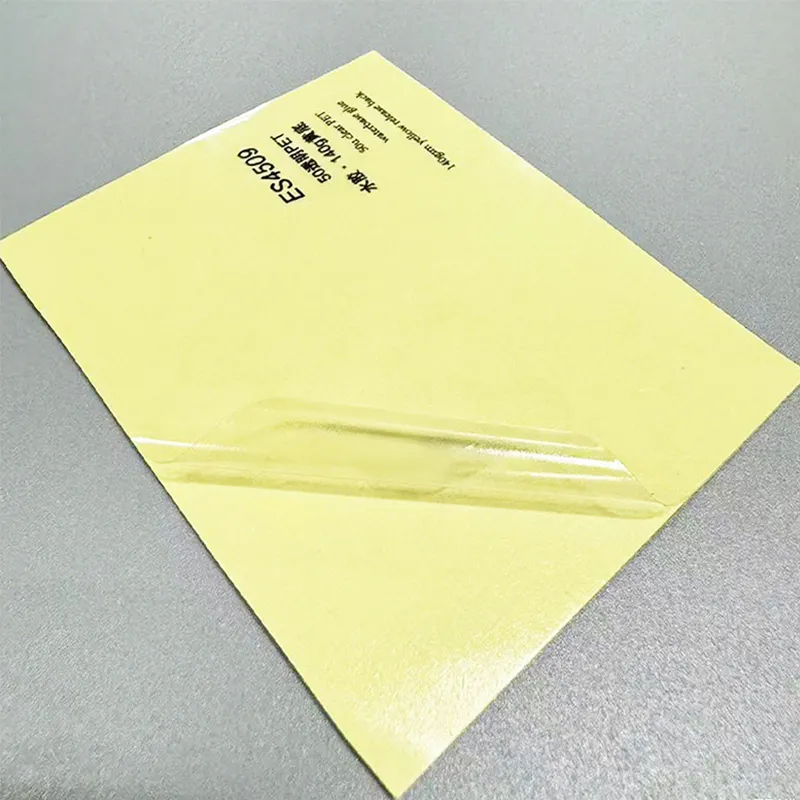

- Made from 25 or 50 Mic clear PET material with water-based adhesive and yellow liners (120gsm for 25Mic and 140gsm for 50Mic versions).

- High transparency with a clear and glossy finish supporting various high-resolution printing methods including digital, flexographic, offset, silkscreen, and UV printing.

- Strong adhesion and performance under temperature and moisture fluctuations.

- Flexible (25Mic) for high-speed labeling or stronger and more stable (50Mic) for industrial-scale applications with a yield rate over 98% at 200m/min.

- Eco-friendly, recyclable, and customizable in size, adhesive type, liner, and pattern.

**Product Value**

HARDVOGUE’s adhesive plastic films offer tailored packaging solutions that not only improve brand presentation but also optimize production efficiency and supply chain management. The high durability and precision in manufacturing reduce material waste, ensuring cost-effectiveness in large-scale industrial labeling and packaging projects, particularly for B2B clients in food & beverage, cosmetics, electronics, pharmaceuticals, and retail sectors.

**Product Advantages**

- Premium matte appearance combined with excellent protective properties.

- Superior printability enabling vibrant, clear images and text.

- Stable and consistent processing on automated lines, reducing downtime and material waste.

- Compliance with global quality certifications and environmental standards.

- Strong technical support including OEM services, customized designs, free samples, and international after-sales assistance.

**Application Scenarios**

- Food & Beverage: Bottle labels and packaging films requiring high transparency.

- Cosmetics & Personal Care: Adhesive films that stick firmly on curved or humid surfaces.

- Pharmaceutical & Healthcare: Clear identification, abrasion resistance, and tamper-evident sealing.

- Retail Packaging: Enhances product visibility and brand appeal on shelves.

- Electronics Packaging and other B2B labeling requiring efficient, high-quality adhesive films.

If you need me to tailor the summary for a specific audience or format, feel free to ask!