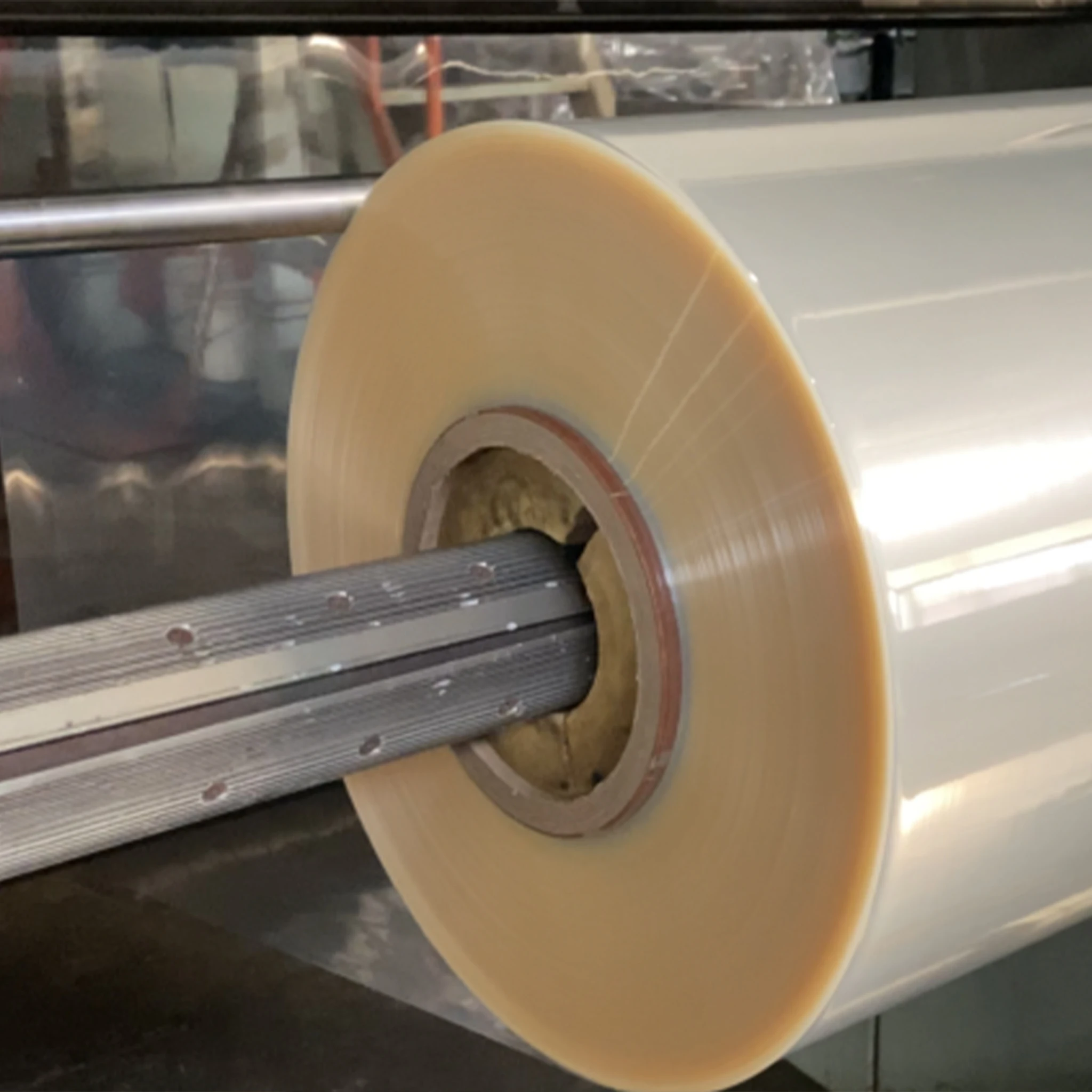

Transparent PETG Shrink Film Custom Printing High Shrink Ratio for Bottle Packaging

Key Features

-

Premium Material: Made from food-grade PETG with excellent clarity and outstanding strength.

-

High Shrink Ratio: Delivers stable and uniform shrinkage for a perfect fit on various bottle shapes.

-

Custom Printing: Supports high-definition multi-color printing with vibrant and long-lasting colors.

-

Safe & Eco-Friendly: Fully recyclable and compliant with global environmental regulations.

-

Surface Protection: Scratch-resistant, moisture-proof, and stain-resistant to keep packaging looking pristine.

Advantages & Value Proposition

-

Brand Enhancement: High transparency combined with high-definition printing reinforces a premium image.

-

Differentiated Competitiveness: Customized designs make products stand out on store shelves.

-

Global Compliance: Meets FDA, EU, and other international food contact safety standards.

-

Eco-Friendly Trend: PETG recyclable material supports sustainable development initiatives.

-

Cost Efficiency: High shrink ratio minimizes material waste and improves production efficiency.

introduction to PETG transparent film

PETG Transparent Film is a high-clarity, thermoformable polyester film made from Polyethylene Terephthalate Glycol (PETG). Known for its excellent optical transparency, toughness, and chemical resistance, PETG transparent film is widely used in applications requiring visibility, strength, and formability. It is easy to print, cut, and thermoform, making it ideal for packaging, protective barriers, face shields, displays, and labels. PETG film is also recyclable and does not release harmful substances during processing, making it a sustainable choice for both industrial and consumer-facing products.

How to customize PETG transparentfilm

Choose Thickness & Width – Select based on your application (e.g. labels, packaging, forming).

Surface Treatment – Options include corona, anti-fog, or scratch-resistant coatings.

Color & Finish – Available in clear, matte, or tinted variations.

Printing Compatibility – Customize for UV, offset, or flexographic printing.

Formability – Adapt for thermoforming or vacuum forming.

Additives – Add UV protection, flame retardants, or anti-static agents.

Compliance – Ensure it meets FDA, REACH, or RoHS standards.

Special Effects – Add textures, holograms, or brand embossing.

Our advantage

PETG transparent Film Application

FAQ

- The materlal and thickness or we give you professional suggestion).

- The quantity and usage.

- If it is possible, show us the photo or send us design is much more better.